Latest News

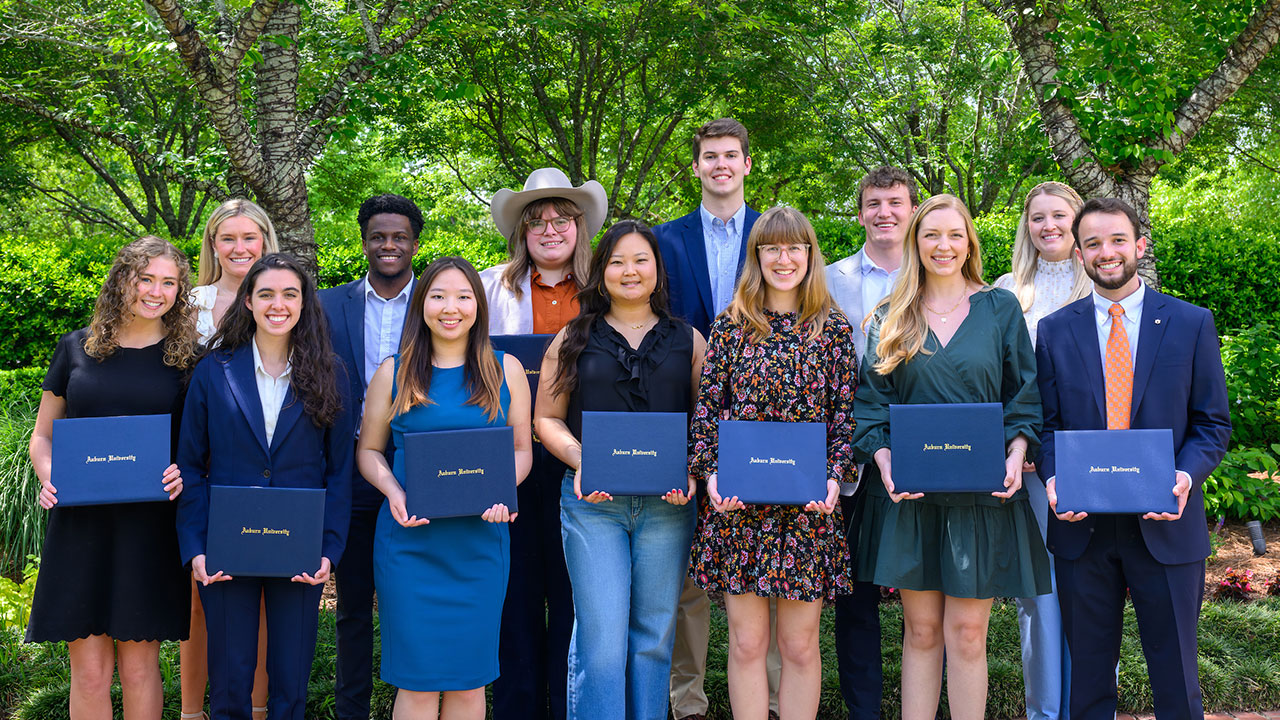

Auburn University honored academic excellence on April 16 when President Christopher B. Roberts presented the President's Awards to more than a dozen deserving students and faculty.

.png)

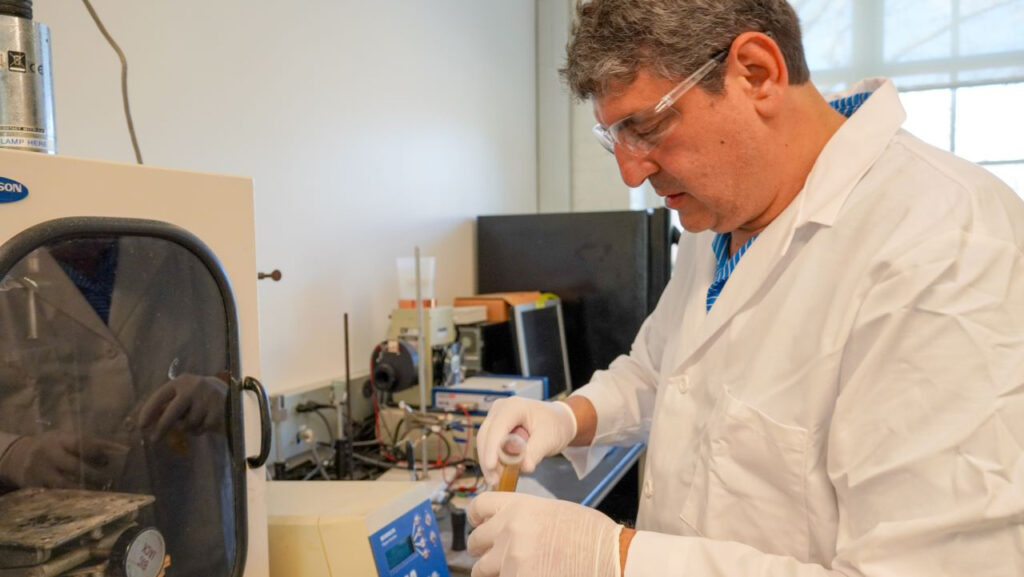

Henry “Hal” Schenck honored by world’s largest scientific society

The McCrary Institute has been awarded a $10 million Department of Energy grant in partnership with Oak Ridge National Laboratory.

Following a national search, Jennifer Mueller-Phillips has been named the ninth dean of the Raymond J. Harbert College of Business. Mueller-Phillips, who has been serving as the interim dean since Sept. 2023, will officially begin on May 1.

Auburn's impact and presence in Huntsville was on full display for the April meeting of the university's Board of Trustees.

A partnership between Auburn and the Los Alamos National Laboratory will enhance collaboration in research, education and workforce development via the Weapons Production-Technology and Nuclear Training Program.

Auburn scientist leads research team developing an Outdoor Recreation Access and Participation Survey to fill a longstanding gap.

The Auburn University Research and Innovation Campus will become a base of technical support operations for the Space Development Agency.

Auburn's Harrison College of Pharmacy now ranks among the top 30 colleges of pharmacy in the nation, according to the U.S. News & World Report’s ranking of 2024 Best Graduate Schools. This ranks among the top 20% of colleges of pharmacy in the country, first in the state of Alabama and sixth in the southeast.

CFWE professor Burak Aksoy developed two products to reduce waste in commercial aquaculture feed pellets and meat products intended for human consumption.

AbGlo is a fitness device that corrects lumbar position during core strength exercises through visual and sensory feedback.

Auburn University's RFID Lab has added Swiss company EM Microelectronic to its board.

The annual day of giving is back for its ninth year on April 10.

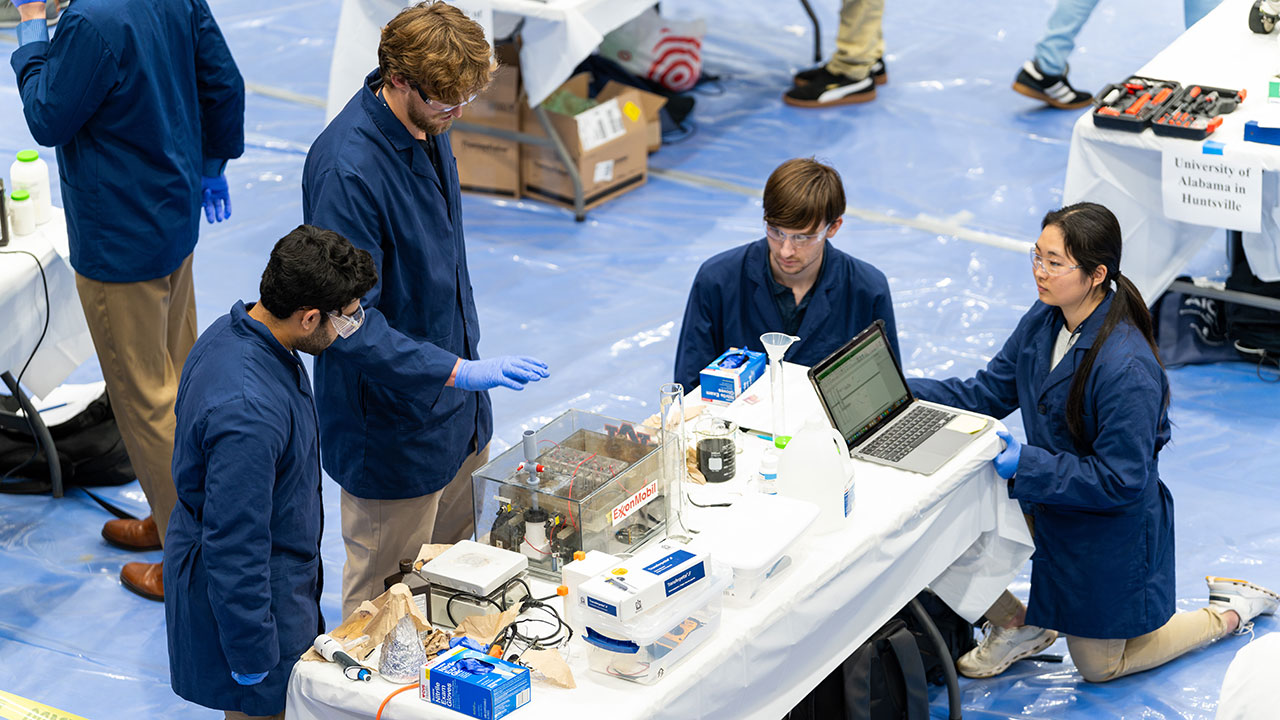

Not only did Auburn host the national organization’s Student Southern Regional Conference, but Auburn chemical engineering students won first place at the regional Chem-E car championship, finished a close second in Chem-E Jeopardy and captured top honors in the technical presentation and research poster competitions.

Support includes quick reviews and waived application fees.

Search

Auburn in the News

-

April 11, 2024TIME

-

April 12, 2024The Conversation

-

April 03, 2024WSFA-TV Montgomery

-

April 03, 2024CNN

-

March 28, 2024EdScoop